Case Study

XR LOTO

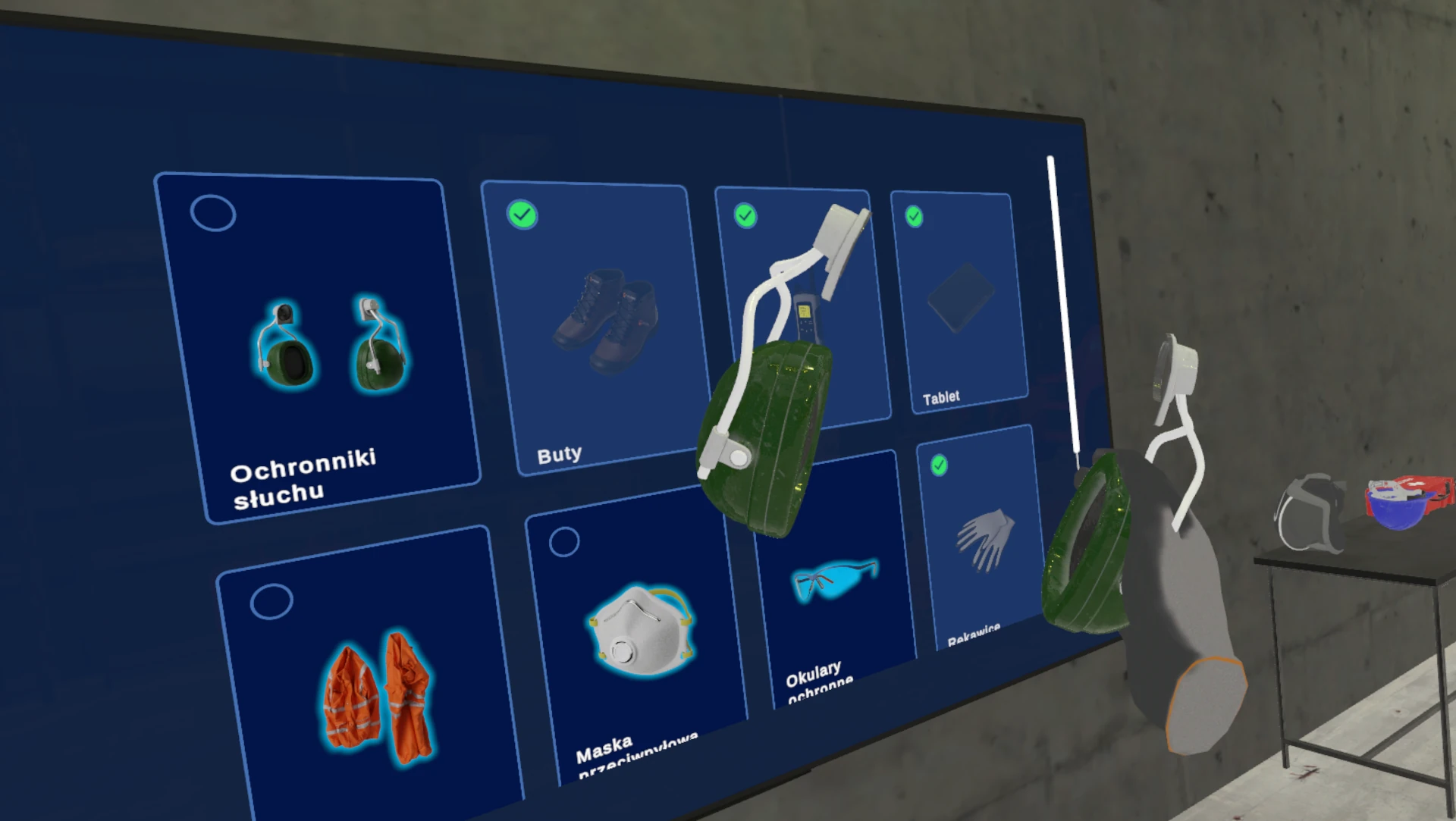

XR LOTO is a virtual reality application that simulates the execution of specific lockout/tagout (LOTO) instructions, individualized for a given infrastructure, and blocking energy in a digital plant environment. XR LOTO is a virtual reality application that simulates the execution of specific lockout/tagout (LOTO) instructions, individualized for a given infrastructure, and blocking energy in a digital plant environment.

Lockout/Tagout Training in VR

The safety of our employees is our top priority, and adopting cutting-edge technologies is key to achieving this goal. Introducing Lockout/Tagout (LOTO) training in VR has been a game-changer for our safety procedures," says John Smith, Head of the Health and Safety Department at XYZ Cement Plant. "What makes this training truly unique is that it takes place within a digital twin of our actual production facility. Employees navigate through a virtual replica of our plant, following the exact energy isolation procedures that we use in real life. This not only ensures that the training is highly relevant to their everyday tasks but also builds familiarity with the workspace without any operational disruptions." The VR training offers two modes: Training Mode, where users learn step-by-step how to safely isolate energy sources in a guided environment. Test Mode, where they independently execute the procedures. At the end of the test, they receive detailed feedback on their performance, highlighting areas for improvement. "The ability to practice in a risk-free virtual environment is invaluable. Employees can repeat procedures until they achieve mastery, significantly reducing the likelihood of mistakes in real-life scenarios. The detailed feedback provided after each test mode session allows us to identify knowledge gaps and tailor additional training as needed." John emphasizes the broader benefits of this approach: "The use of a digital twin takes this training to the next level. It bridges the gap between theory and practice, immersing participants in an environment that feels as close to reality as possible. This leads to better engagement, higher retention of knowledge, and, ultimately, improved workplace safety. We are proud to be at the forefront of using VR and digital twin technology to enhance our safety culture.

What makes this training truly unique is that it takes place within a digital twin of our actual production facility. Employees navigate through a virtual replica of our plant, following the exact energy isolation procedures that we use in real life. This not only ensures that the training is highly relevant to their everyday tasks but also builds familiarity with the workspace without any operational disruptions

The implementation of this VR-based training has not only elevated safety standards but also underscored the company’s commitment to innovation and employee well-being.

How a Digital Twin Reduced Costs in Designing a New Facility Installation

Test the performance of new equipment and layouts in a virtual environment, identifying potential issues or inefficiencies early in the process.

Ensure the new installation would fit seamlessly into the existing infrastructure, preventing costly redesigns or rework.

Avoid the risks associated with physical prototyping or making changes once construction has begun.

Provide a single source of truth for all stakeholders, ensuring alignment between design, engineering, and operations teams.