Case Study

XRay

Discover how our Digital Twin solutions transform industries trough practical, real-world applications and succes stories

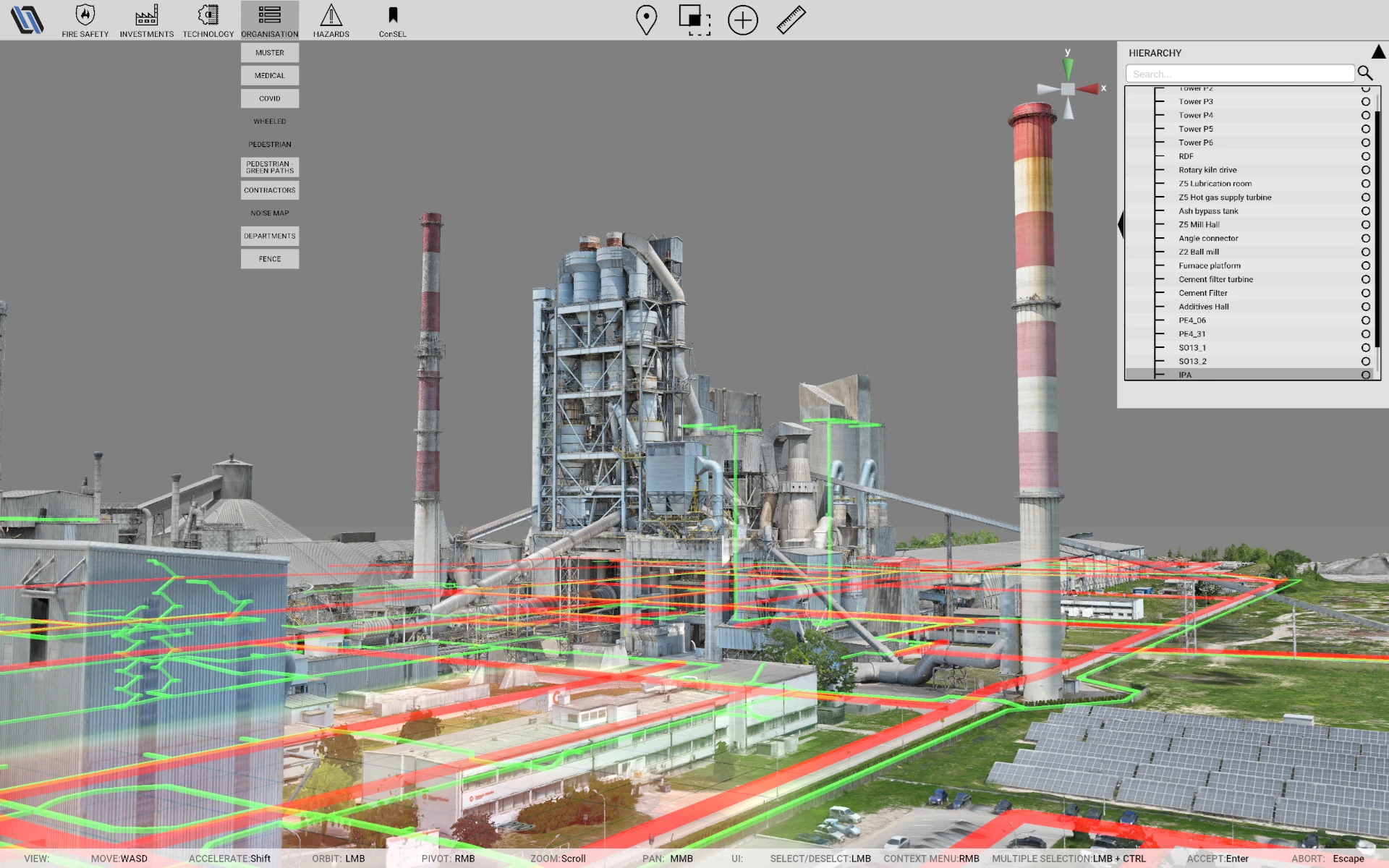

How a Digital Twin Reduced Costs in Designing a New Facility Installation

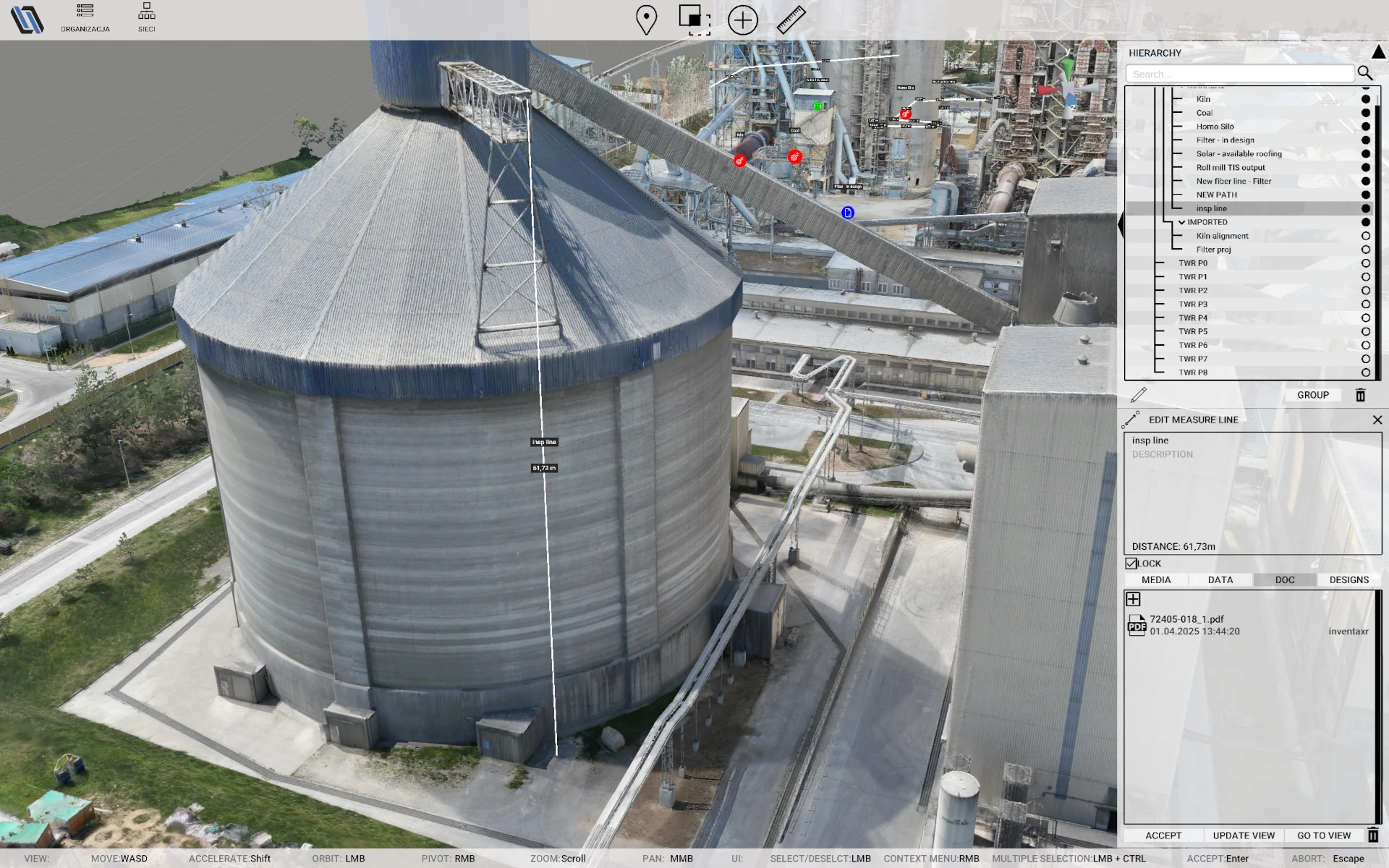

Transforming Maintenence in Cement Manufacturing

XRRAY revolutionizes predictive maintenence by accurately forecasting equipments needs. This proactive approach minimizes downtime and significantly reduces operational costs.

Run Simulations, Minimize Risk, Collaborate More Effectively, Optimize Space and Resources

Explore our data-driven visualizations showcasting succesfully predictive maintenence implementations.

Transforming Energy Efficiency in Cement Production with XRRAY

Discover how our XRRAY solutions has revolutionized energy consumption in cement production. This case study highlights significant reductions in energy usage and operational costs.

Run Simulations: Test the performance of new equipment and layouts in a virtual environment, identifying potential issues or inefficiencies early in the process. Minimize Risk: Avoid the risks associated with physical prototyping or making changes once construction has begun. Collaborate More Effectively: Provide a single source of truth for all stakeholders, ensuring alignment between design, engineering, and operations teams. Optimize Space and Resources: Ensure the new installation would fit seamlessly into the existing infrastructure, preventing costly redesigns or rework.

Implementing a Digital Twin has significantly lowered the costs associated with designing and implementing new installations at our plant," says Sarah Thompson, Head of the Investments Department at ABC Industrial Facility. "Traditionally, designing a new installation involved a lot of trial and error. We had to rely heavily on physical models and manual calculations, which were time-consuming and costly. With the Digital Twin, we created a precise virtual replica of our existing facility, allowing us to plan, simulate, and test the new installation before any physical work began.

Implementation Timeline of XRay Solutions

Work on the Client’s site. We collect the data required for model development. The first output we obtain is a point cloud – a digital inventory of the object. For us, this serves as the starting point for creating an accurate 3D model.

The collected data is processed by our team to create a photorealistic 3D model of the object, reflecting the level of detail required by the Client.

Information layers and application functionalities agreed upon with the client, tailored to the individual needs of end users.

Each implementation concludes with training for end users. At a date agreed upon with the Client, we provide the knowledge necessary to make full use of all the functionalities of the XR Ray application.

Client Feedback

"Incorporating a 3D model digital twin of our facility into our operations has revolutionized the way we approach both day-to-day maintenance and large-scale projects like our annual kiln overhaul,"

“Implementing a Digital Twin has significantly lowered the costs associated with designing and implementing new installations at our plant,” says Sarah Thompson, Head of the Investments Department at ABC Industrial Facility. “Traditionally, designing a new installation involved a lot of trial and error. We had to rely heavily on physical models and manual calculations, which were time-consuming and costly. With the Digital Twin, we created a precise virtual replica of our existing facility, allowing us to plan, simulate, and test the new installation before any physical work began.